We established a target to remove all plastic from our packaging and make it 100% recyclable by 2030.

Throughout the VELUX Group, we are transitioning to single-material, recyclable, plastic-free packaging. This new packaging is designed to deliver high levels of protection and can be disposed of in one waste stream for recycling.

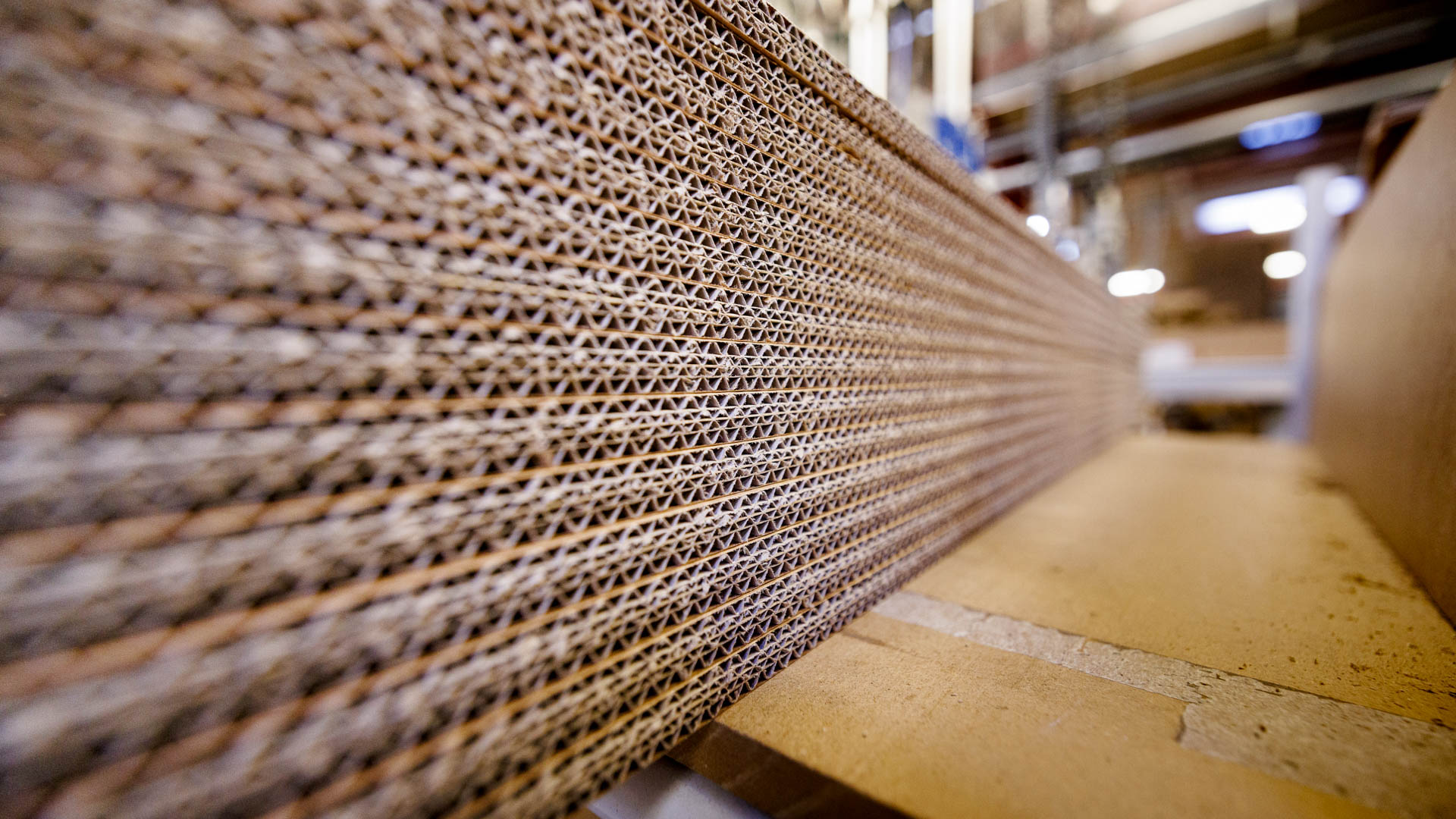

The journey to paper-based packaging

In 2021, we started work on developing the new plastic-free packaging and it has already been implemented on our main roof window and flashing products in Europe. This means European installers can now dispose of all packaging in one waste stream, which saves time and increases convenience.

In the US, we have implemented paper-based packaging for our main flashings products and have started work on converting the packaging of our other products.

The plastic-to-paper packaging

Although it sounds simple, transitioning from plastic to paper-based packaging presents a variety of challenges. The process for our main roof windows has taken over two years and involved design professionals, engineers and production companies.

The main challenge is that the paper-based packaging has to deliver the same level of protection and performance as the previous EPS (expanded polystyrene) packaging. To create the strength needed to protect the window during transport and when in storage, we tested various paper-based materials extensively. These tests showed that a paper-based material with honeycomb panels could withstand stacking pressure, knocks and blows, as well as humidity and temperature changes.

Another demand for the new paper-based packaging for our main roof windows was that it could run in the existing packaging equipment with minimal disruption. This meant that each packaging element was implemented individually to ensure it would work before the next element was introduced. The first element to be switched was the tape followed by the glass support element. It took 18 months to replace all the plastic packaging elements with paper-based versions.

The vast majority of our residential roof window products in Europe are now packaged in paper-based packaging, which has resulted in more than 400 tonnes less plastic packaging sent to customers in 2024 compared to 2021.

Ever since our founding, the VELUX Group has been shaped by our Model Company Objective.

In 2023, we embedded sustainability into our corporate strategy, making it a core element of our business and an integral part of all aspects of our organisation - from supplier selection to product design and end-of-life management.