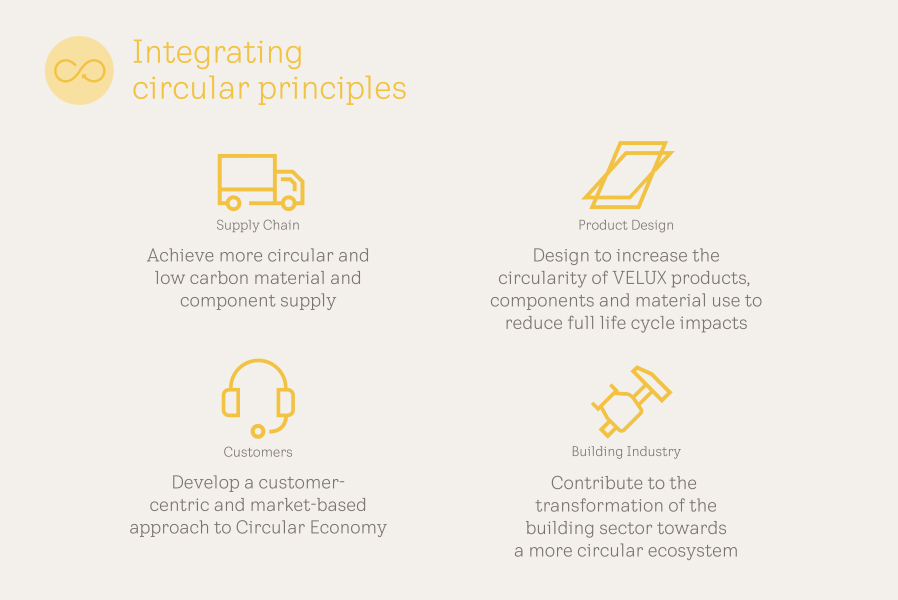

Throughout the VELUX Group, we are looking for new ways to eliminate waste and keep valuable resources in use. This extends to all parts of our business – from sourcing materials with recycled content to working with partners in the industry to introduce greater circularity throughout the building sector. In 2023, we developed a strategic framework and governance strategy to address opportunities and impacts across four focus areas. This framework forms the foundation of our work with circularity.

Circularity across the value chain

At VELUX, we are working to embed circularity across our value chain. From sourcing and design to production, use, and end-of-life, our approach includes:

- Designing for Circularity: We have introduced circular design guidelines and an internal evaluation tool to guide our product development teams in creating solutions that are durable, repairable, and recyclable.

- Sourcing Recycled Materials: We prioritize materials with higher recycled content and lower carbon.

- Reducing Operational Waste: We are working towards zero waste to landfill from production and a 50% reduction in hazardous waste by 2030.

- Investigating Circular Business Models: We are testing new services such as refurbishment and take-back schemes to extend product lifetimes and reduce environmental impact.

Circularity in action: Pilot Projects

To bring our circular ambitions to life, we are testing a series of pilot projects in selected markets. These initiatives help us understand how circularity can be practically implemented and potentially scaled:

- Take-Back Schemes in the Netherlands: We are scaling up a service to collect and disassemble used VELUX roof windows, aiming to ensure that the recycled materials maintain as high a value as possible.

- Refurbishment in Denmark: We are testing how windows up to 20-years-old can be cleaned, repaired, and updated to extend their usability, showing what a second life for windows might look like.

- Proactive Maintenance and upgrades in Germany: Two pilots in Germany are exploring how proactive maintenance, repairs and upgrades can increase the lifespan of installed solutions and ensure optimal performance.

These pilots are building insights that influence product development, service design, and circularity practices across our value chain.

Sourcing recycled materials

We already have several partnerships in place to support our aim of increasing the recycled content in our products. For example, we work with Novelis – the world’s largest aluminium recycler. They are providing us with high recycled content flat-rolled aluminium for use in our products. We also work with Arcelor Mittal who provides us with low-carbon emission steel that is produced using a minimum of 75% scrap steel and 100% renewable electricity.

Through partnerships like this, we can reduce our reliance on virgin resources used and extend the lifetime of the valuable materials we use in our products.

Built to last

We produce high-quality roof windows and accessories and have confidence that they will last for many years with occasional maintenance and cleaning. In the rare event that our products do not meet our customers’ expectations, we offer the following guarantees:

- 10 years for VELUX pitched and flat roof windows, sun tunnels, and sealing products

- 3 years for interior blinds and insect screens, external shutters and blinds, motors, and accessories for solar and electric products

- 3 years for solar or electric external blinds and anti-heat blinds

- 2 years for roof windows for uninhabited spaces

We use high-quality materials in our products and always consider the impact of materials on the environment. That’s why 100% of the wood we use comes from forest partners certified to the FSC- and PEFC Responsible Forest Management standards.

The journey to zero-plastic packaging

At VELUX Group, we have high ambitions for both the quality and performance of our packaging. We are transitioning to single-material, recyclable, plastic-free packaging that does not compromise on protection and enables installers to dispose of all packaging in one waste stream.

We have launched paper-based packaging for our roof windows and flashings in Europe. This makes it easier for customers to dispose of the packaging for recycling. We are also transitioning to these new packaging materials for other products and outside Europe, as we aim to ensure single-material packaging with zero plastic that is 100% recyclable by 2030.

Zero production waste to landfill

As part of our ambition to increase circularity in our business, we are working actively to reduce production waste. By 2030, we aim to send zero production waste to landfill and reduce absolute hazardous production waste by 50% compared to 2020. In order to meet our ambitious target, we will continue to implement waste reduction initiatives, increase best practice sharing between production sites and partner with waste management companies.